F:Air Jet Water Separator(special Version) / Other

Air Jet Water Separator(special Version)

Air Jet Water Separator(spesial Version) Series㉓

■Model JAC-37-2

Blowing off waterdrop adhered on the defrosted tuna&Shortening the operation time at the next process

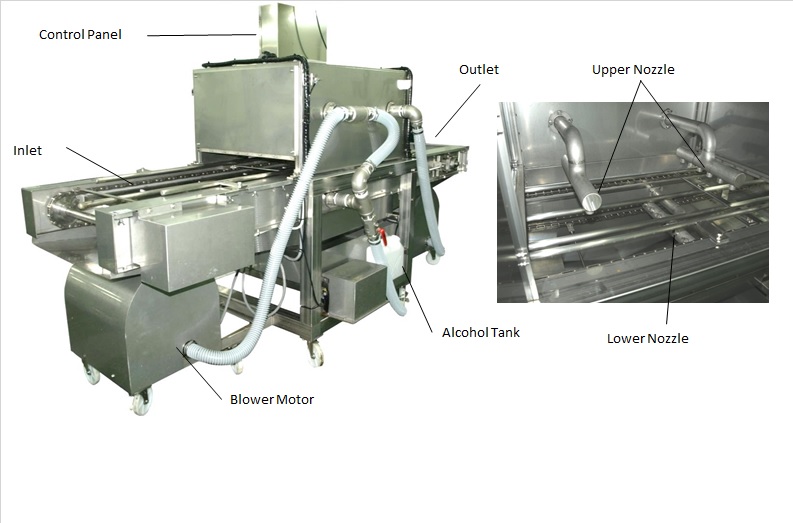

Characteristic

・Compact design & high efficency

High processing performance, thansk to the ultimately minimized machine with energy saving design and variable conveyor speed 5 - 20 m/min.

・More hygienic design with high cleaning

performance

- Made of the material SUS304

- Enable to wash out completely, provided double front doors

- Sterilized by alcohol atomizing system after the cleaning

・Easier mainternaciability

No worry even during the cleaning

operation mode, thanks to the application of water proof type instrumentations

including operation switches.

Enable

easier maintenance & adjustment,

thanks to the water proof frame / cover with those simplified design

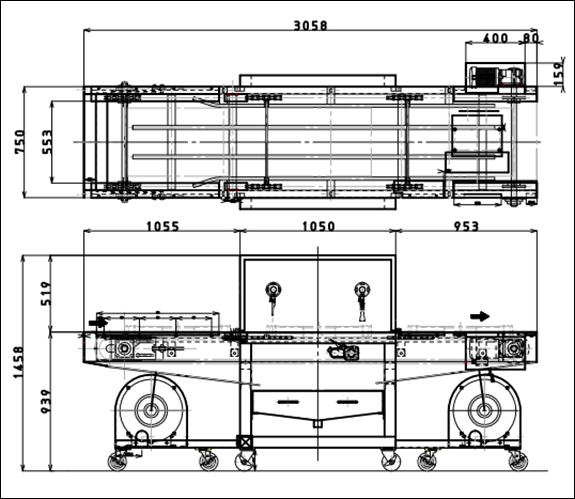

■Mechanical Dimensional Drawing

■Specification

Water blowing -off after defrosting tuna

Flat Blade Setting Gauge

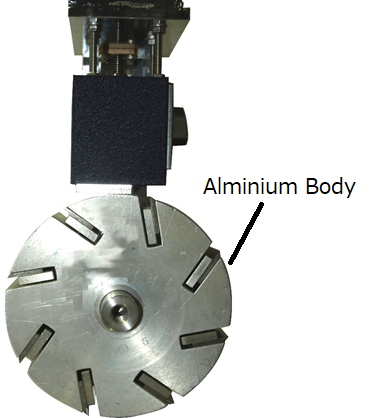

Flat Blade Setting Gauge Series㉔

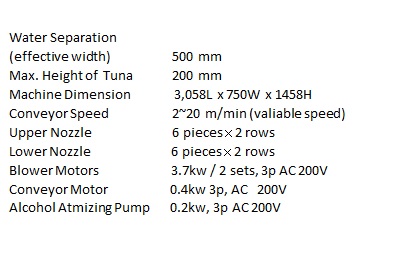

■Flat Blade Setting Gauge

How to operate

Everybody can set the flat blade easily.

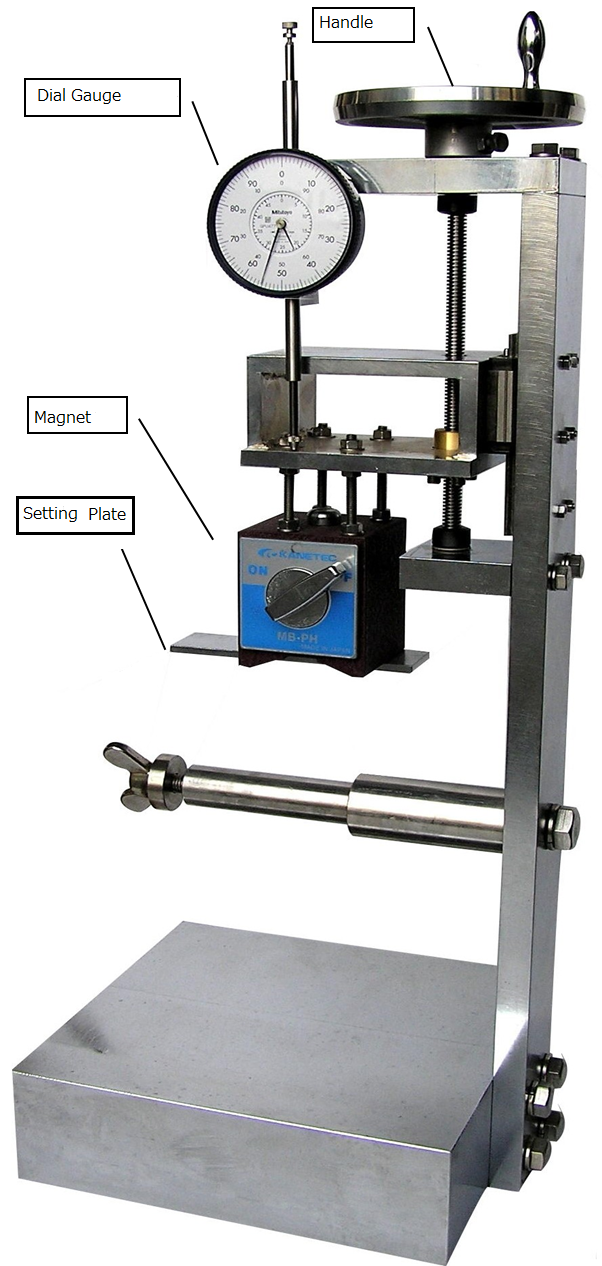

1.Insert flat brade, back plate, and specified bolt into .

the cutter's body, but without tightening the bolt, yet.

2.Move the setting plate by the handle up to the

cutter's body and adjust the dial gauge there to zero position.

3.Then, lift up the setting plate up to any arbitrary

position (normally 0.5 mm - 0.8 mm) without energizing the magnet.

4.Rotate the cutter's body and position the flat brade

at the center of the setting plate. Energize the magnet.

Then, the flat brade is lifted up and set to the proper position.

5.Tighten the fixing bolt gradually.

(Repeat the above 4 & 5.)

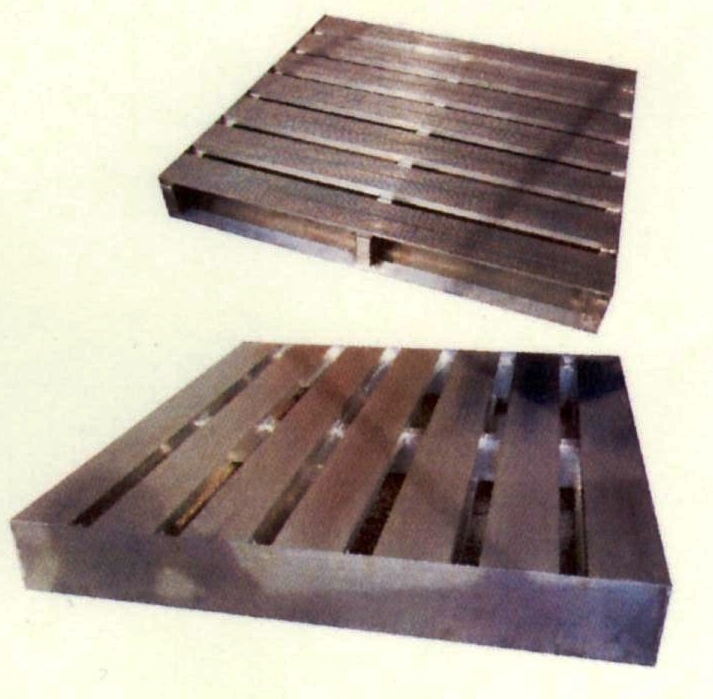

Pallet for deep freeze refrigerator

Pallet for deep freeze refrigerator Series㉕

■Pallet for tuna and oceanic bonitos

■Aluminium Pallet for oceanic bonitos and tuna